An exquisitely detailed 1903 handmade ceramic floor

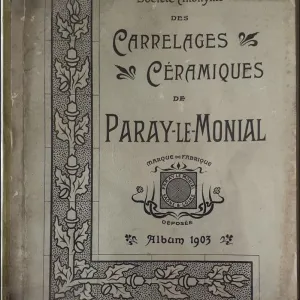

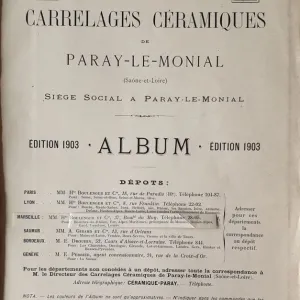

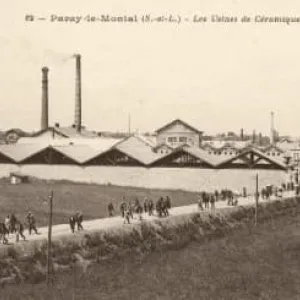

This exceptional, museum-quality ceramic floor originates from the esteemed usine of Carrelages Ceramiques de Paray-le-Monial, Saone et Loire in Burgundy, France and dates to 1903. It is a fine example of the artistic and technical brilliance of Paul Charnoz—an innovator of ceramic art who honed his craft at Boch Frères in the late 19th century before founding his celebrated workshop in Paray-le-Monial.

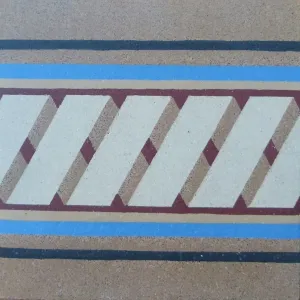

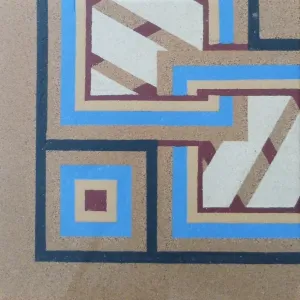

The floor design showcases remarkable attention to detail and mastery of technique. At its heart lies a principal field tile of striking, almost airbrushed quality finesse, bordered by an elegant same size helix motif. These border tiles are enhanced by the presence of a blue jewel motif linking tile, creating a rhythmic and sophisticated interplay between form and color. All tiles have been carefully reclaimed and thoughtfully restored, preserving the integrity and charm of the original craftsmanship.

Comprising 110 square feet, the floor is in excellent condition—arriving with you meticulously cleaned and ready for installation.

High resolution photographs of a randomly selected section of the floor are accompanied by scans from the original 1903 catalogue, providing invaluable historical documentation and provenance. The durability of its high-firing process makes it suitable for both interior and exterior settings, and it will perform excellently with modern underfloor heating systems.

Inventory Overview:

- Field Tiles: 281 pieces – approximately 93 sq. ft.

- Helix Border Tiles: 36 pieces + 4 corner tiles

- Blue Jewel Link Tiles: 11 pieces

- Total Border Coverage: Approximately 29.3 linear feet

This floor is not merely a surface—it is a legacy of French ceramic artistry, a testament to the aesthetic and technical vision of Paul Charnoz, and a unique opportunity to incorporate a piece of 20th-century design heritage into a contemporary space.

Note:-

Our antique tiles were originally handmade in single or two tile molds. Pre-computer fabrication these molds were machined by hand & the colour slips to create the tile were mixed by measure and eye. When firing the tiles, the kiln temperatures of c.1,100F degrees could also be variable. The result of this production process is that tiles made during this period of non-automation often display subtle size & thickness variations and there can be tonal variations in colors, all of which add to their charm and uniqueness. When photographing a floor, we always take a random section so that it is representative of the whole in tones and patina.

A rigorous quality control during the restoration process will include in the sale any tiles with groutable small chips and edge nibbles, expected of tiles more than 100 years old, but include for free any with larger defaults as rejects, which the tiler can then use for offcuts.

Can we help?

If you can provide a technical drawing, or a simple sketch with key dimensions, we are happy to assist in evaluating and recommending the best layout of the floor in your area of choice. Click here for more details